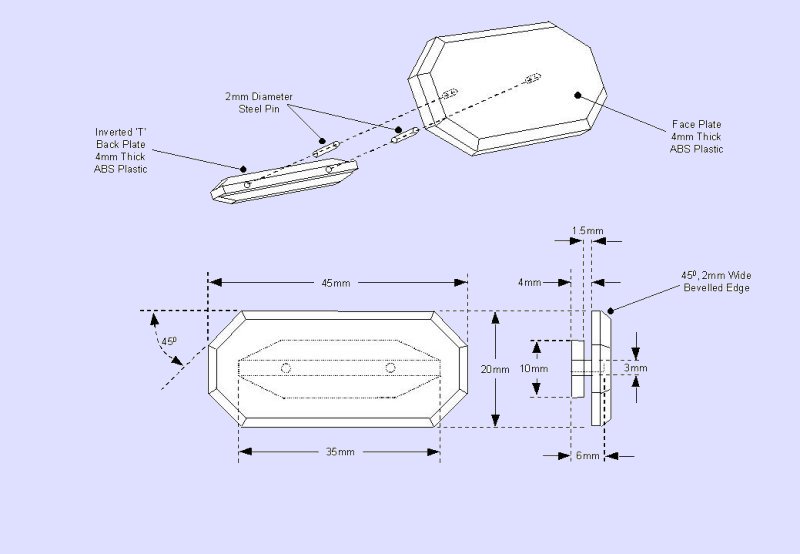

| Final Assembly

Each cover is finally assembled as follows:-

1. Holding the face plate and back plate together in the correct 'final' position (both long axes aligned centrally and the back plate centred onto the back of the face plate in an inverted 'T' position - bottom/foot of the 'T' against the back of the face plate) clamp them across the corner of the vice such that both the holes in the back plate are visible. Using a hammer and a small panel pin or similar mark through the holes into the back of the face plate.

2. Disassemble the face plate from the back plate. In the back of the face plate, at the marks made, drill 2 x 2mm holes to a depth of 2mm i.e. only half way through the face plate.

3. Glue a 2mm diameter, 6mm long steel pin into each hole in the back of the face plate ensuring the pin is fully located into the hole.

4. Using the methylated spirit (or similar) and applicator cloth or cotton bud, thoroughly clean the mating surfaces of the front plate and back plate and allow to dry.

5. Apply glue to the mating surfaces of the face plate and back plate and slide the back plate over the steel pins and into contact with the back of the face plate.

6. The cover is now completed and should be put aside for at least 24 hours to allow the glue to fully cure.

Although each cover is now complete the face of the cover can be further decorated. Those shown in the photograph have had a 16mm x 16mm lapel pin badge glued centrally on the face plate. This requires a very small clearance hole to be drilled through the centre point of the face plate to clear the 'pin' at the rear of the lapel badge. Additionally a larger diameter hole is then drilled concentric with the first small hole to a depth of 3mm to clear the locating stub on the back of the lapel badge and allow it to sit flat on the face plate. The lapel badge is then simply glued into position.

|